Factory design is the most important and first step to create a work that is aesthetically pleasing, optimal in terms of technical solutions as well as functions. The design requires a team of engineers and architects with expertise and experience to handle well the problems encountered in the ideation process.

Before designing the plan, the team of architects and engineers of Nhan Dat Construction always learns about the industry, current and future production scale of the investor, and geographical stratigraphy. quality, construction location… to come up with the most reasonable solution.

Factory design requirements

Industrial factories and factories are a type of building with specific characteristics, but still an architectural form.

The consulting and design of the factory needs to meet at least the following 3 factors:

reasonable function diagram

This is the first and prerequisite factor to meet the needs of investors in the future. A function diagram is calculated and arranged reasonably to help the production process go smoothly and smoothly, creating the highest labor productivity.

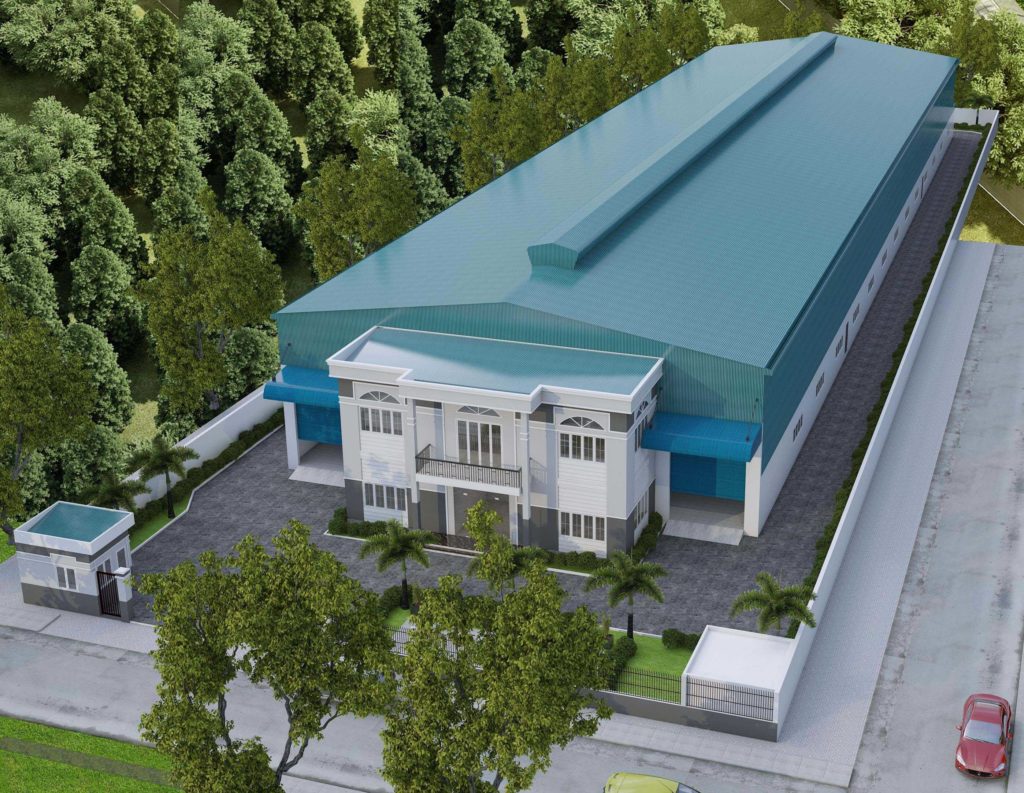

Creating a beautiful and aesthetic architecture

The concept of industrial factory without regard to aesthetics is no longer relevant. In addition to the function of being a warehouse to gather materials, raw materials or dusty, hot factories, industrial buildings are increasingly being demanded and paid more attention by investors. With the dedicated advice of architects, the factory building will become much more harmonious and beautiful.

Optimizing economic – technical solutions

The design must ensure a stable safety factor for the factory structure system. Construction measures, technical solutions during the process of construction of factories need to be taken into account right from the drawing design stage, the selection of finishing materials also needs to be considered and considered. carefully.

Some beautiful factory samples at the end will give you some ideas.

The design of the workshop should be noted:

- Ensures the structure’s ability to withstand adverse conditions during manufacturing.

- Convenient traffic diagram between stages in the production process.

- Possibility to renovate and expand the factory area in the future.

- Ensure the requirements for tree density, construction density, requirements for fire prevention and environmental discharge (EIA)

- Create for employees a cool working space, full of natural light to save energy and increase productivity.

Factory design steps

Like civil works, industrial factory design can be divided into 2 steps:

Basic Design

Basic design is the first step providing preliminary architectural and structural solutions. Basic design drawings include:

- Drawing of the factory floor plan

- Architectural drawing of the factory: Plan, section, facade of the factory.

- Structural drawings: Foundation solutions and body structure solutions

- Factory functional diagram drawing

- Basic design drawing is also part of the application for a factory project license

Design of construction drawings

Construction design drawings show in detail and fully all items of the project including the following parts: Architecture, structure, M&E. Project items include:

- Main factory, warehouse

- Internal Road

- Office

- Canteen, staff motel

- Gateway, fence, guard house

- Substation, powerhouse

- Water tank, pump house

- garage

- Other ancillary works

Industrial factory design consultancy unit price【In 2021】

Factory design unit price:

According to the state unit price norms, the design costs are calculated according to the total construction investment of the investor. Design value from 2% – 3% of total investment.

A company specializing in design and construction of factories, industrial houses, Nhan Dat Construction has its own calculation and policies:

- According to construction area: Unit price from 40,000 – 50,000 VND/m2 (Depending on requirements) design requirements, each type of factory, the complexity of the project)

- When signing the contract to build the factory, the cost of design consultancy is reduced by 50%.

Factory design consultancy documents of Nhan Dat Construction include:

1. Project explanation includes architectural explanation and factory structure calculation explanation

2. BOQ table and detailed specification of work volume and material specification

3. Design drawings include:

- Planning of the total floor 1/500

- Structural drawings for items

- Architectural drawing and overall project perspective

- Electro-mechanical drawings including basic parts: Electricity, water supply and drainage, lighting,…

4. The company’s legal profile includes:

- Certificate of practice of individuals

- Register for business

- Certificate proving the organization’s capacity for construction activities

Company Nhan Dat Construction is a professional factory design and build unit in the South region of Vietnam. With dedicated architects and engineers with many years of experience, a team of skilled workers and a system of modern machinery. We always strive to create the best quality products at the most reasonable prices.

For more reference: Price list for construction of pre-engineered steel frame factory in 2021< /a>

Frequently Asked Questions

Question 1: Can the design of a pre-engineered steel building make a basement?

The answer is yes. There have been many typical and famous projects in the world today, steel structure is selected as the main bearing structure solution for the project; can be mentioned as:

- Taipei Tower: The tower has 101 floors on the ground floor, with 5 basements

- World Trade Center: This building is a dose of the US 9/11 earthquake

Question 2: How many steps does the design of steel frame industrial buildings include?

- Step 1: Receive information from customers about the implementation project. From there design the structure of the work, the overall floor plan, the sub-work system and the applied technology.

- Step 2: Provide a design profile of the factory’s perspective drawing. The drawing needs to be completed to every detail including: fire protection system, electrical engineering design, wastewater treatment,…

- Step 3: The next step is to make a basic estimate according to the contract to design steel frames for industrial buildings.

- Step 4: If the two parties agree with the design as well as the implementation estimate, then proceed to prepare the technical design document in the most detailed way.

- Step 5: Handing over the completed design documents to the customer and starting the construction.

Question 3: What is Tekla design software? Its outstanding application in steel structure design?

Tekla Structures is a building information simulation software capable of modeling structures that incorporate different types of building materials, including concrete, steel, wood, and glass. Tekla Structures helps engineers build 3D models, create 2D drawings, and access construction information

Tekla application in steel structure design:

- Create the most accurate, complex 3D models of buildings

- Manage accurate 2D production drawings

- Manage and use information throughout from preliminary design, detailed design to construction

Question 4: Do pre-engineered steel buildings need a construction permit? What is the red line in the design of pre-engineered steel buildings?

Applying for a construction permit is a mandatory procedure when building houses in general and pre-engineered steel buildings in particular (according to state regulations in some specific cases, it is not necessary to apply for a construction permit).

The red line is the boundary line determined on the planning and actual map to demarcate the boundary between the land used for construction of works and the part reserved for traffic roads or other areas.public spaces or other technical infrastructure works. In urban areas, the red line is the entire roadbed, sidewalks and sidewalks.

Question 5: Construction density in the design of pre-engineered steel buildings?

Construction density is the ratio of the land area occupied by constructions to the total land area (excluding the land occupied area of works such as swimming pools, decorative miniatures, and sports fields). outdoor sports, except for sports fields and tennis courts that are built permanently and occupy space on the ground, ..

SEE MORE CHANNEL:

https://www.youtube.com/watch?v=mtAFPs1OPTg